Physical AI for Agriculture AGRIST

AGRIST conducted development and testing of physical AI at the Microsoft AI Co-Innovation Lab KOBE.

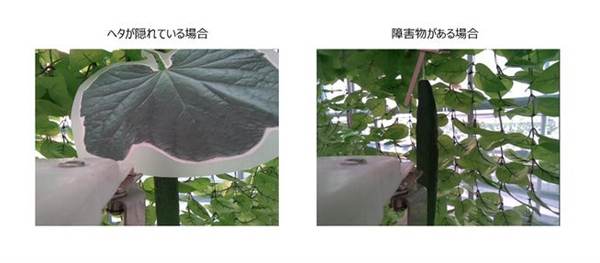

This testing focused on cases where the robotic arm of an automatic harvesting robot cannot properly approach a target due to real-world factors such as hidden stems or obstacles. Using images as input, the AI calculated the recommended turning angle, and provided this as an API callable by the automatic harvesting robot via Azure Functions. This confirmed the entire process leading to robot operation.

Starting from the on-site challenges of automatic harvesting robots, AGRIST is working to improve AI recognition and prediction capabilities and develop a system that can withstand on-site operation.

With automated harvesting robots, the path of entry for the robot arm can be restricted not only by the position and angle of the target object, but also by the surrounding environment such as leaves, stems, and supports, which can result in failed harvesting operations and loss of time. For this reason, the company has now begun development and testing to improve harvesting performance using “physical AI,” which converts the results of AI inference into instructions that the automated harvesting robot can actually use and provides in a format that makes it easy to keep up with environmental changes.

The company says it has seen promise in the effectiveness and scalability of physical AI as an approach to increasing harvesting success rates (harvesting performance).

※Translating Japanese articles into English with AI