Remote Collaboration in Product Development Using the IOWN APN NTT docomo business and Dassault Systèmes

NTT docomo business and Dassault Systèmes successfully demonstrated the world’s first remote collaboration in real-time 3D CAD for product development using the IOWN APN.

This demonstration utilized Dassault Systèmes’ 3DEXPERIENCE platform to synchronize 3D design and PLM solution data at high speed and low latency, enabling seamless collaboration across multiple locations as if they were in the same place. This will improve productivity, particularly in the manufacturing industry, and will combine NTT docomo business’s AI-Centric ICT platform initiative, including the APN, with Dassault Systèmes’ technology to build a 4D digital platform, part of the IOWN initiative.

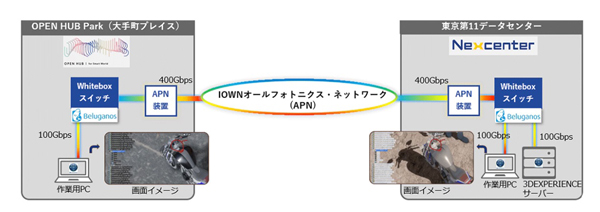

In the demonstration, Tokyo Data Center No. 11 in Musashino City and OPEN HUB Park in Otemachi Place were connected via APN, and remote collaborative editing was performed using the 3DEXPERIENCE platform. On the Musashino City side, a 3DEXPERIENCE platform desktop application was installed, allowing for real-time sharing and editing of the same 3D CAD model, and a server storing the 3D CAD data, while on the Otemachi Place side, a work PC running the 3DEXPERIENCE platform desktop application was installed.

Between these two locations, thousands to tens of thousands of large-volume, high-resolution, and multiple types of 3D CAD and PLM data were downloaded from the server, and collaborative editing using 3D CAD was verified.

デモ(demo)

The results confirmed that collaborative work could be performed with roughly the same performance as when the server and workers’ PCs were connected within the same building. Furthermore, when we measured the time it took for the editing environment in 3D CAD to synchronize, we confirmed that the speed was up to approximately 500% faster than the conventional method via the Internet, and that smooth real-time synchronization with almost no delay was possible.

※Translating Japanese articles into English with AI