Manufacturing DX in Indonesia OKI

OKI and Indonesia’s Netmarks have signed a partnership agreement to expand the Indonesian market for the “Projection Assembly System,” which helps to eliminate work errors at production sites.

OKI will strengthen its sales channels and customer base in the market and deploy the system.

Netmarks will provide one-stop local sales, installation support, and maintenance support. The collaboration between the two companies aims to solve issues facing Indonesia’s manufacturing industry, such as production efficiency and quality standardization.

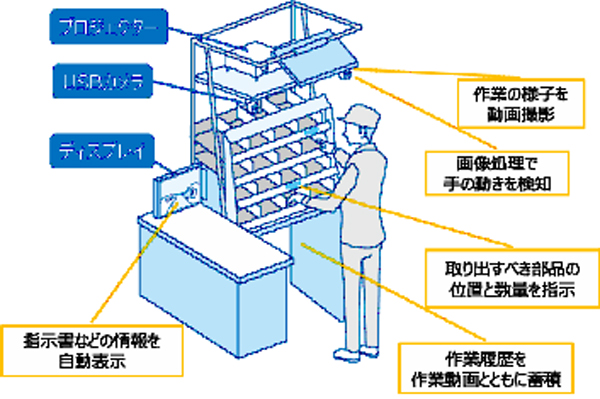

OKI’s “Projection Assembly System” is a solution that supports “on-site transformation” as part of “Manufacturing DX,” which realizes smart factories.

It combines projection mapping and image sensing technology and has been introduced in many manufacturing companies in Japan to help eliminate work errors at production sites.

Netmarks has more than 20 years of experience in the sale, construction, and maintenance of IT solutions in Indonesia, and has a strong sales channel and customer base, and also has an established local support system.

Currently, as Indonesia’s economy grows, there is a demand for improving factory production capacity and ensuring quality at international standards, but there are also challenges such as standardizing the quality of the workforce and improving work efficiency.

※Translating Japanese articles into English with AI