NTT DATA calls for overall optimization of the logistics industry and “relay transport optimization”

On July 10, NTT DATA held a briefing on the challenges facing the logistics industry and the company’s efforts. As is well known, the logistics industry in Japan is facing the “2024 problem.” The Work Style Reform Act has limited the annual overtime work hours of drivers to 960 hours, making long-distance transportation difficult, and there are concerns that goods will not be able to be transported as a result.

According to NTT DATA’s research, the logistics industry is characterized by an overwhelming majority of small and medium-sized businesses and a multi-contract structure. This makes it difficult to improve the efficiency of transportation. In fact, the loading rate is said to be less than 40%. Another characteristic is that shippers have an extremely strong position, which causes inefficiencies.

When we think of logistics problems, we think of things like redelivery of parcels, but that’s not necessarily the case. Of the logistics industry’s market size of 28.5 trillion yen, truck transportation accounts for 19 trillion yen, of which 16 trillion yen is business-to-business (B2B) transportation, and home delivery is about 3 trillion yen. Moreover, home delivery is an oligopoly market dominated by five major companies. The breakdown of B2B transportation is 4 trillion yen for major companies and 12 trillion yen for small and medium-sized companies. Looking at it this way, it becomes clear that the main battlefield for logistics issues is small and medium-sized companies, which have a market size of 12 trillion yen.

With the driver shortage being called for, what kind of work are drivers engaged in? In fact, in addition to driving, there are other tasks such as loading and unloading luggage. Loading and unloading luggage, and incidental tasks such as inspection and packing.

Although it varies depending on the company, about 20% of drivers’ working hours are spent on tasks other than driving. Moreover, loading and unloading is the most common reason why drivers apply for workers’ compensation. More than half of drivers who apply for workers’ compensation are absent from work for about a month.

Amid a driver shortage, drivers are tasked with tasks other than driving, which can lead to accidents during those tasks and long absences, creating a confusing situation.

“Such inefficiencies occur between transport companies and shippers,” says Shinsaku Minamida, head of the Sustainability Services & Strategy Promotion Office at NTT DATA’s Consulting Business Headquarters. “Each one is a small thing, but they add up and cause inefficiencies. According to our calculations, these things add up to about 3.7 trillion yen in inefficiency. 3.7 trillion yen may be an exaggeration, but we think the figure is right”.

The only way to solve these issues and increase sustainability is to optimize the entire industry. In other words, it means making it possible to transport more goods with fewer drivers. Digitalization is the key, but the company argues that digitalization in the logistics industry will not work unless it is carried out across the entire supply chain.

“Efficiency will not improve unless shippers, transport companies, and warehouse operators digitize together. Currently, various efforts are being made to address the 2024 problem, but most of these are being made by large companies. This will not address the real issues facing the logistics industry, which is dominated by small and medium-sized businesses,” said Director Minamida.

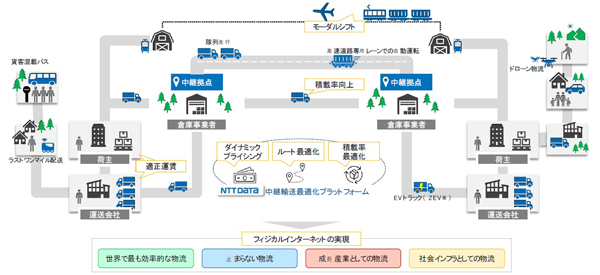

In light of this reality, the company proposes a solution to the problem through “relay transport optimization”.

As mentioned above, the 2024 problem is caused by drivers being unable to transport long distances. If you are no longer able to drive long distances, you will inevitably have to transport goods by relaying them somewhere.

Relaying by ferry is an option, but ferries take a long time to transport. Moreover, coordinating with each party and setting up ferry relays is a considerable effort for small and medium-sized businesses, making it unrealistic.

One way to relay by truck is to transship. In other words, the goods are transshipped and transported at a relay point. However, this creates new loading and unloading operations.

The other option is to switch vehicles. The driver is replaced at the relay point, and the goods are transported to the destination by the same truck. Using a trailer is an option, but a trailer costs tens of millions of yen each, making it difficult for small and medium-sized businesses to purchase one.

Director Minamida explains, “Only large businesses with many drivers and trucks can switch vehicles. It is difficult for small and medium-sized businesses to share one truck with multiple drivers. If you think about it that way, transshipment seems to be the basic direction.”

NTT DATA is considering transshipment of cargo between multiple locations, rather than just transshipping cargo between two locations at a relay point.

“It will be a complicated system because multiple businesses are involved, but it will increase the chances of matching. In one-way relay transport, there is usually no cargo on the return journey, so in order to be able to load cargo on the return journey, it is better to have multiple businesses work together” (Director Minamida).

To achieve this, the company is considering optimizing transport using data. For example, one scenario would be for warehouse operators to take the lead in aggregating transport-related data and resolving the issue by arranging the entire relay transport using an optimal transport calculation platform.

“Physical Internet” is also a key point. The physical internet is a business model in which, instead of digital information, goods are relayed between logistics centers in various regions by trucks, freight trains, ships, airplanes, and other means of transport.

Since long-distance transport will no longer be possible, sustainable transport can only be achieved by building a relay transport network, and in the process, modal shift will also progress. Modal shift is the shift from transporting goods by truck to using rail and ships, and with the optimization of relay transport, rail is likely to become the most efficient means of transporting goods long distances. A trend will likely emerge in which goods are transported by rail first, and then transferred to trucks for transport.

Director Minamida points out, “We want to optimize logistics as a whole and make it sustainable. This is not a problem that can be solved by large businesses alone. The essence of the problem lies with small and medium-sized businesses, so unless we solve that, the 2024 problem will not be resolved”.

※Translating Japanese articles into English with AI