Reusing metal scraps generated during the manufacturing process NTT Data, Zam Technologies and others establish method

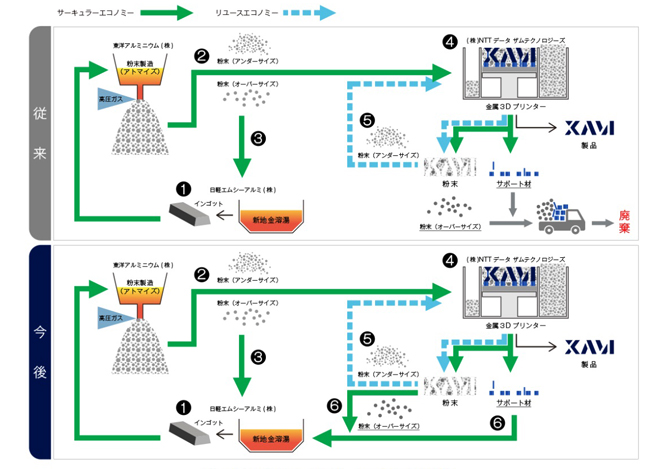

NTT Data Zam Technologies, Toyo Aluminum, and Nikkei MC Aluminum have established a method to recycle metal scraps generated during the manufacturing process of metal 3D printers, which were previously treated as industrial waste, achieving a circular economy.

By remelting what was previously disposed of as scrap metal, almost 100% of the waste can be reused.

The realization of this circular economy not only makes it possible to manufacture products with reduced CO2 emissions, but also reduces disposal costs, which leads to lower costs for parts manufactured with 3D printers and increases market competitiveness.

NTT Data Zam Technologies will be in charge of manufacturing and quality assurance using metal additive manufacturing. Nikkei MC Aluminum is in charge of manufacturing ingots of mother alloy powder for 3D printers. Toyo Aluminum will be in charge of manufacturing alloy powder for 3D printers using the atomization method.