AI optimally cultivates microorganisms Chitose Research Institute

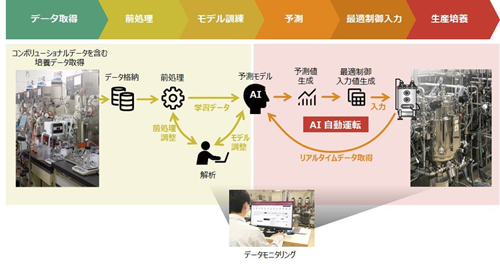

Chitose Research Institute has developed an AI automatic culture control system that uses AI to control the culture conditions of microorganisms to the optimal state.

The company’s unique feature is that it has newly defined the learning data necessary for AI learning in the development of functional food ingredients using microorganisms, which relies on human experience and know-how, and has developed sensing technology to acquire this data. As a result of conducting a demonstration experiment using this system in joint research with Kyowa Hakko Bio, it was found that AI was able to control culture that is difficult for humans, and achieved higher production than the conditions set by experts in microbial culture.

At Chitose Research Institute, they started by redefining the learning data necessary for microbial culture in order to replace microbial culture, which has been done with “craftsmanship”, with control using AI. In biology, optimal culture conditions have been sought by exploring the causal relationship between data obtained from various sensors in culture tanks and the amount of target compounds and bacterial cells. On the other hand, the data that AI is trained on does not need to be such that humans can understand its causal relationships. By capturing ”some changes” occurring within the culture tank and having AI learn from them, it is possible to find correlations between data and culture conditions and make predictions.

Believing that the “conventional data” obtained from culture tanks is insufficient to describe the events occurring inside the culture tank, they independently developed a variety of sensor devices that had not previously been used in biology.

Chitose Research Institute named the data group obtained from this unique device ”convolutional data” and created an AI model that uses appropriate preprocessing and learning to predict culture conditions with high accuracy. This AI model has made it possible to infer optimal culture conditions based on predictions and automatically control culture to achieve optimal conditions.