Labor-saving data center operation with digital twin NTT COMWARE

2022 Hokkaido Business EXPO, one of Hokkaido’s largest business events, was held in Sapporo on the 10th (Thursday) and 11th (Friday).

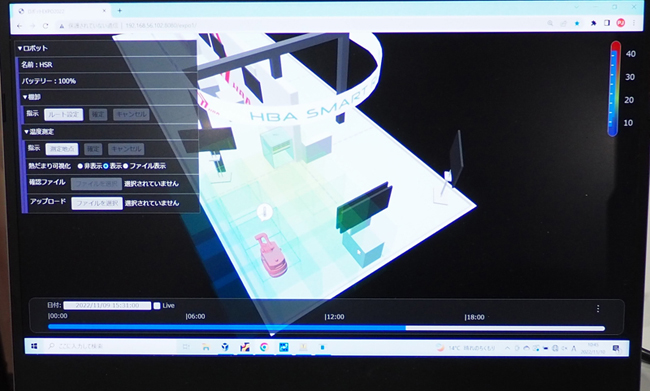

NTT COMWARE jointly exhibited with HBA for the first time. He introduced HBA’s automatic patrol inspection robot “HSR” that realizes facility inspection work such as data centers and plants, and digital twin solutions that focus on IOWN promoted by NTT Group and other companies.

The two companies are collaborating and working on a demonstration experiment of data center operations. Specifically, HSR is used to grasp the operation status of the data center and to take recovery measures when a failure is detected, and the collected data and operation status are displayed in 3D space with NTT Comware’s data analysis and utilization platform “Smart Data Fusion”. It accumulates and analyzes digital twins using technologies such as the viewer “4DVIZ,” which accumulates a large amount of information and grasps overall trends, and is promoting labor saving in data center operation work.

Mr. Wataru Imazato, Executive Officer of NTT COMWARE, General Manager of Business Planning Department, Network Cloud Business Headquarters, said, “Various solutions are created by repeating the cycle of analyzing the data acquired in the real space as a digital twin and feeding it back to the real space. It is a so-called cyber-physical system (CPS), but we expect the business to spread widely through a model that connects the real and the digital.”

Two use cases were shown at the exhibition booth.

One is the case of having robots manage when the arrangement of racks is changed in inventory work in a data center.

“This work was traditionally done by staff, but we envision having robots automatically patrol the area, analyze the acquired data on the digital twin, feed back the analysis results to the robot, and let the robot manage it.” explains Atsushi Kawaguchi, General Manager of the IOWN Solution Department of the company’s IOWN Promotion Department.

The other is a solution that uses temperature sensors and cameras mounted on robots to detect heat buildup around server racks in data centers and issue alerts.

“Dealing with heat pools that cause hardware failure is an important activity for data center operation, but it is difficult to detect heat pools in the data center with normal temperature sensors. (Mr. Kawaguchi).

Takashi Shimazu, General Manager of the IOWN Solution Department of the company’s IOWN Promotion Department, said, “By acquiring and accumulating data, the optimum state of the data center can be derived. If the optimum state is known, any state that deviates from it can be identified as abnormal. What is it? We also know what caused the malfunction and what can be done to restore it.We believe that optimization will lead to autonomous operation, and that is also the goal we are aiming for with the digital twin.”

Advanced technology unique to the company is also incorporated into the robots that automatically run in the data center. By combining a LiDAR sensor and a VPS (Visual Positioning System), autonomous driving that does not rely on radio or GPS is realized.

Yoshinori Tsuzuki, Manager of the Technology Strategy Department of the company’s IOWN Promotion Department, said, “Automatic driving is made possible by extracting feature points from the images recognized by the robot and identifying its own location based on the feature points. Wireless and GPS. The feature is that it can drive automatically even indoors where it is difficult to use.”